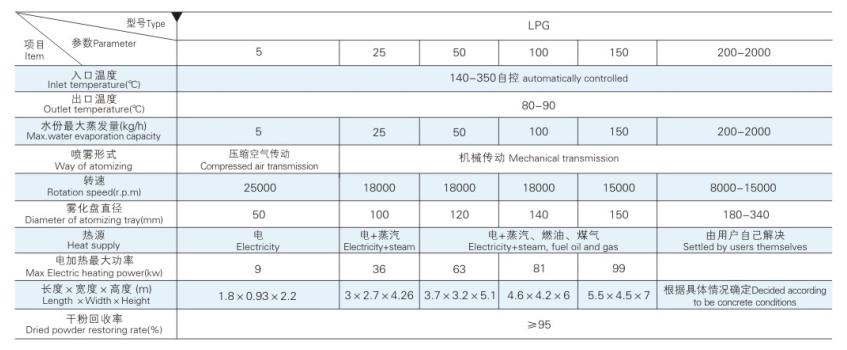

LPG series high speed centrifugal spray dryer

spray drying is a technology widely used in the liquid process molding and drying industry. The technology is most suitable for preparing powder, granules or bulk solid products from solutions, emulsions, suspensions and pumpable paste materials. Therefore, spray drying is one of the most ideal technologies when the particle size and distribution, residual moisture content, bulk density and particle shape of the final product must meet precise standards.

The drying speed is fast. After the material liquid is sprayed, the surface area is greatly increased. In the hot air flow, 95% -98% of the water can be evaporated in an instant. It only takes a few seconds to complete the drying time. The product has good uniformity, fluidity and solubility, high purity and good quality. The production process is simple, the operation and control are easy, the moisture content of the material liquid is 40-60% (the special material can reach 90%), and it can be dried into a powder or granular product at one time. After drying, there is no need for crushing and sorting, thus reducing the operation process in production and improving the purity of the product. The particle size, bulk density and water content of the product can be adjusted by changing the operating conditions within a certain range, which is very convenient for control and management.