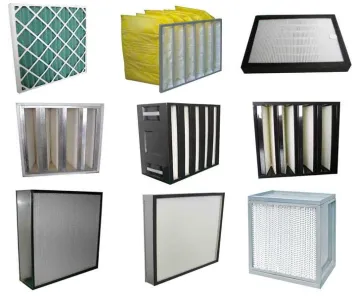

Clean room air filter

1. Product classification

(1) According to the filtration efficiency, the primary effect filter can filter particles with a diameter of more than 5 μm, and the cost is low. It is mostly made of domestic high-quality non-woven fabrics, glass fibers and synthetic fibers through special blending, or imported polyester fibers as filter materials. Common types include primary effect plate filters, primary effect paper frame filters and primary effect bag filters. Primary effect plate filters are generally used in fresh air units, trends, etc. in direct contact with the outside air; primary effect bag filters are widely used in central air conditioning and ventilation systems, as well as in industrial purification scenarios such as pharmaceuticals, hospitals, electronics, and food. They can also be used as front-end filters for medium-effect filters to prolong the service life of medium-effect filters. Medium efficiency filter: suitable for filtering particles of 1 - 5μm, commonly used in central air conditioning and integrated air supply system, can carry out primary filtration of air conditioning system, protect the high efficiency filter in the system and the system itself. In places where the cleanliness of air purification is not high, the air filtered by the medium efficiency filter can be directly sent to the working area. Sub-high efficiency filter: high filtration efficiency for particles above 0.5μm, can be used as a pre-filter of high efficiency filter, further improve the purification effect and reduce the load of high efficiency filter. High-efficiency filter: The filtration efficiency of 0.3 μm particles is above 99.97%. Like baffle-free high-efficiency filter, it is widely used in the air supply at the end of the air conditioner in the dust-free purification workshop of optical electronics, LCD liquid crystal manufacturing, biomedicine, precision instruments and other industries. High-temperature resistant high-efficiency filter can be used for a long time in the 400 ℃ environment. The air volume is large, the resistance is small, it is non-combustible, the chemical resistance is good, and the moisture absorption is low. (2) According to the type of equipment, the fan filter unit (FFU) is an air filtration equipment with its own fan. It is equipped with high-efficiency filter (HEPA or ULPA). It is widely used in clean rooms, laboratories, hospitals and other places with high air quality requirements. 2. Performance advantages (1) High-efficiency filtration Clean room air filters use advanced filter materials and technologies, which can achieve efficient interception of tiny particles. The filtration efficiency can reach more than 99.99%. They can effectively remove dust, microorganisms, harmful gases and other impurities in the air and ensure that the clean indoor environment reaches extremely high cleanliness standards. (2) Long-life design By optimizing the structure and material selection of the filter, its service life can be extended, the frequency of replacement can be reduced, and the cost of use can be reduced. When designing some filters, the uniformity of air flow distribution will also be considered to avoid excessive local filtration load and further extend the service life. (3) Low-resistance operation Optimized airflow design can reduce the resistance of air passing through the filter, improve the efficiency of air circulation, and thus save energy. Low resistance operation not only helps to reduce the energy consumption of the air conditioning system, but also reduces the wear and tear of the equipment and prolongs the service life of the equipment. (4) Intelligent management Combined with the Internet of Things technology, the clean room air filter can realize remote monitoring and intelligent maintenance. The operating status of the filter is monitored in real time through sensors, such as resistance, pressure difference and other parameters. When the filter needs to be replaced or maintained, the system will issue an alarm in time to remind the staff to deal with it and improve management efficiency. III. Applicable Scenarios (1) Semiconductor Manufacturing Semiconductor production requires extremely high cleanliness. Tiny particles in the air may cause problems such as short circuit of the chip and performance degradation. The clean room air filter can effectively filter the particles in the air, ensure that the production environment meets standards, and ensure the manufacturing quality of the chip. ( 2) The biopharmaceutical pharmaceutical process requires strict control of microorganisms and particles in the air to prevent drug contamination. Clean room air filters can provide a stable clean air for the pharmaceutical workshop to ensure the quality and safety of drugs. In the production process of sterile drugs, high-efficiency filters are even more essential key equipment. (3) Medical places such as operating rooms and sterile wards have strict air quality requirements. Clean room air filters can filter bacteria and particles in the air, reduce the risk of infection, and provide patients with a safe treatment and rehabilitation environment. In the central supply rooms of some large hospitals, air filters are also used to purify the air to ensure the sterile quality of medical apparatus. (4) During the processing of food processing, it is necessary to prevent microbial contamination and ensure food safety. Clean room air filters can filter particles and microorganisms in the air to prevent food from being contaminated during processing and packaging. In some high-end food production workshops, such as baked goods and dairy production workshops, the requirements for air purification are particularly strict.